| Clock & Boost X,R,U (Pin2) |

Direction X,R,U (Pin3) |

GND X,R,U (Pin19) |

| Clock & Boost Y,S,V (Pin4) |

Direction Y,S,V (Pin5) |

GND Y,S,V (Pin20) |

| Clock & Boost Z,T,W (Pin6) |

Direction Z,T,W (Pin7) |

GND Z,T,W (Pin21) |

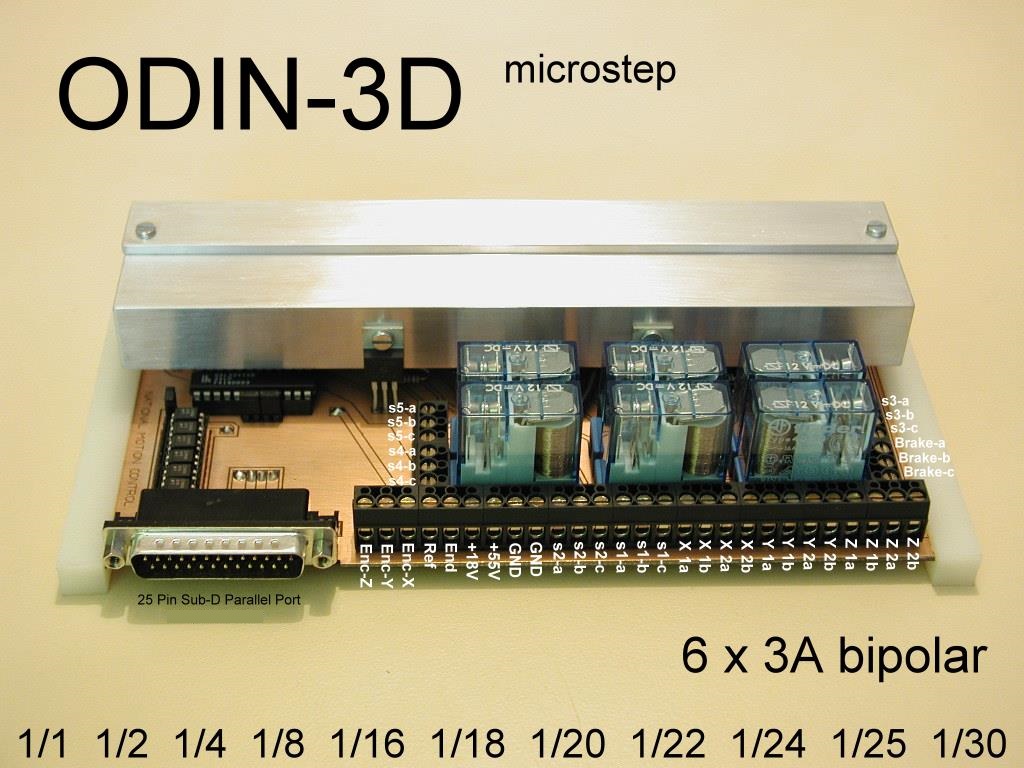

| Spindlemotor-Relay |

s1 (Pin8) |

GNDs1 (Pin22) |

| Coolingpump-Relay (pulsed) |

s2 (Pin9), inverted |

GNDs2 (Pin22) |

| 1.Additional-Relay (Fullversion) |

s3 (Pin14), inverted |

GNDs3 (Pin25) |

| 2.Additional-Relay (Fullversion) |

s4 (Pin16) |

GNDs4 (Pin25) |

| 3.Additional-Relay (Fullversion) |

s5 (Pin17), inverted |

GNDs5 (Pin25) |

| Current Reduction & Hardware Brake |

(Pin1), Fullvers. inverted |

GND (Pin18) |

| Reference-Switch (Pin11) |

Start, when Pin11 Low |

GND (Pin23) |

| End-Switch (Pin10) |

Stop, when Pin10 High |

GND (Pin24) |

| Step-Encoder (Pin12/13/15) |

Auto-Correction of Realpos. |

GND (Pin24/24/23) |